DLC-Diamond Like Carbon coating

Simple description:

Danko diamond-like carbon evaporation vacuum electroplating machine has simple operation and high performance. It is equipped with thermal evaporation system, which can be used for vacuum deposition of thin films and coatings

Product master drawing:

Product master drawing:

Coating Machine/Thin Film Deposition System/Sputtering Coating Equipment/Diamond Like Carbon coating

Product details:

Diamond-like-Carbon coatings are high performing and easy operating, equipped with arc sputtering system, which are used in demanding automotive, non-ferrous material machining and industrial engineering environments where component surfaces are subjected to high contact pressure, intermittent lubrication or dry sliding and rolling environments where severe abrasive and adhesive wear conditions exist. DLC coatings are also commonly applied onto various medical and dental instruments and implants to provide a dark black, anti-reflective and bio-compatible surface with enhanced tribological protection properties.

The company can design vacuum coating machines of various specifications and models according to user requirements. The vacuum unit and electric control system can also be designed and configured according to user requirements.

Product parameters:

Structure Type: Vertical structure or Horizontal structure.

Substrate Material: ABS,PS, PC, PP, PVC, Nylon, TPU (Plastic materials), acrylic glass.

Recommend Machine: Evaporation Coating Machine

Structure Type: Vertical structure or Horizontal structure.

Coating Film: Aluminum, Chrome, Cupper

Color: Silver color, Gold color, Semi-transparency, Red, Blue, Green, Grey, Black, Multicolor

Equipment with: UV line

Consumables in production: Aluminum / Chromium Wires, Paint

Product use:

It is used for coating disposable tableware, plastic artworks, clothing accessories, shoe materials, accessories, glass jewelry, automobile signs, exterior and interior trim parts, automobile wheels and other plastic products

Product picture:

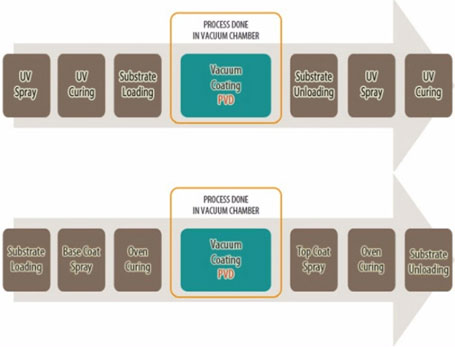

Production process:

Quality control:

Pump: mechanical pump + roots pump + diffusion pump + heat preservation pump (or optional: cryogenic pump, cryogenic pump system)

Limited vacuum: 8 * 10-4Pa (clean room, no-load)

Axis: 6 / 8 / 9 axis

Power supply: resistance heating tungsten wire evaporator power supply, high voltage ion bombardment power supply, thyristor power supply

By manual, semi-automatic, fully automatic, PLC

Product advantages:

Fast film formation and deposition speed

Beautiful color and good distribution

No waste any gas or liquid. Stable operation and good vacuum performance

Customized processing services

High standard quality control