DLC Hard Film Vacuum Plating Machine

SYSTEM SUMMARY

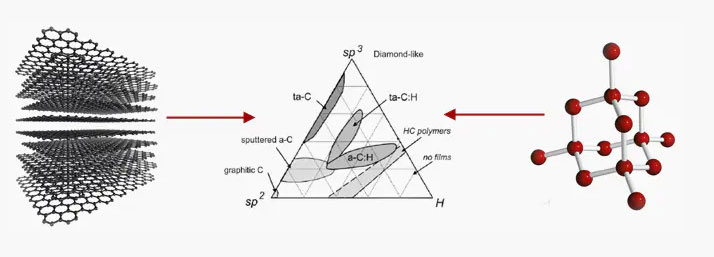

Diamond-like-Carbon coatings are high performing and easy operating, equipped with arc sputtering system, which are used in demanding automotive, non-ferrous material machining and industrial engineering environments where component surfaces are subjected to high contact pressure, intermittent lubrication or dry sliding and rolling environments where severe abrasive and adhesive wear conditions exist. DLC coatings are also commonly applied onto various medical and dental instruments and implants to provide a dark black, anti-reflective and bio-compatible surface with enhanced tribological protection properties.

SYSTEM TYPE

Vertical Batch-Single or double door

APPLICATION:

• Cutting & Forming Tools

• General Wear Resistance

• Military / Armaments

• Aerospace Components

• Automotive Components

• Transportation

• Medical & Dental Tools / Implants

• Decorative / Color

COATING:

TiN, TiC, TiCN, TiAlN, TiAlCN, TiCrN, TiCrN, TiCrCN, TiAlCrN and other multilayer super hard coatings. Danko Vacuum Technology is professional China DLC hard film vacuum plating machines manufacturers and custom DLC hard film vacuum plating machines company ,including but not limited to Sputtering Systems, Optical Coating Units, Batch Metallizers, Physical Vapor Deposition (PVD) Systems, Hard and Wear Resistant Vacuum Coating Deposition Equipment, Glass, PE, PC Substrate Coaters, Roll-to-Roll Machines for coating flexible substrates. our DLC hard film vacuum plating machine are used for a wide range of applications described below (but not limited to) Automotive, Decorative, Hard coatings, Tool & Metal Cutting coatings, and thin film Coating applications for industrial and Laboratories including Universities.Danko Vacuum Technology Company Ltd is committed to expand our market boundaries by providing high-quality, high-performance DLC hard film vacuum plating machine.