Medical Instrument Coating Machine

Simple description:

Danko medical instrument Coating Machine is high performing and easy operating, equipped with arc sputtering system. This machine offers a wide range of application, such as hard film coating, abrasion resistance coating and exterior coating on tools of cutting, stamping, molding and metal die-casting, with DLC (diamond like coating) function to improve the hardness.

Product master drawing:

Product labeling:

Coating Machine/Thin Film Deposition System/Sputtering Coating Equipment/Medical instrument

Product details:

This model is designed for hard and super hard protective coatings on tools,cutter and mould. The vacuum sealing of chamber and the interior design and material of moving parts are under consideration of high-temperature bear,assembling high efficiency roundness arc evaporation source or rectangular flat arc evaporation source.We can also install hollow cathode gun and impact resistance bias power supply, to ensure the density and reactivity of plasma,increase the compactness and adhesion of coatings,Substrates can be three-dimensional motion,to enhance the uniform of coating.The full automatic control processing is steady and perfect.It can deposit TiN,TiC,TiCN,TiAICN,TiCrN,TiCrCN,TiAICrN,multilayer super hard coatings,which is used in precision mould industry(dies,shear mould,standard mould and moulding mould etc),tool industry(drill,hard alloy,milling cutter,broacnes,screw tap and gear cutter ect.) and automobile industry(piston,piston rings and alloy wheels etc.).

The company can design vacuum coating machines of various specifications and models according to user requirements. The vacuum unit and electric control system can also be designed and configured according to user requirements.

Product parameters:

Substrate Material: tools, cutter and mould

Recommend Machine: Multi Arc Ion Coating Machine

Structure Type: Vertical structure, #304 Stainless Steel

Coating Film: Multi-functional metal film, hard film, DLC film

Film Color: multi colors, gun black, titanium golden color, rose golden color, stainless steel color, purple color and other more colors

Film type: TiN, TiC, CrN, ZrN, TiCN, TiCrN, TiNC, TiALN and DLC

Consumables in production: Titanium, Chromium, Zirconium

Product use:

It is widely used in precision mould industry, tool industry and automobile industry

Product picture:

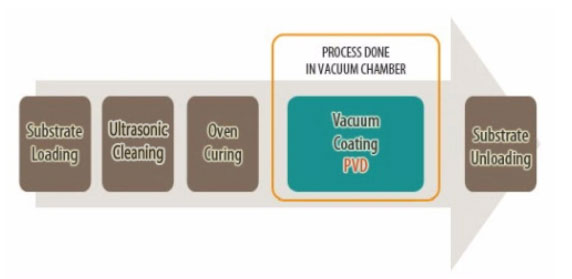

Production process:

Quality control:

Pump: mechanical pump + roots pump + diffusion pump + heat preservation pump (or optional: cryogenic pump, cryogenic pump system)

Gas system: 1-4 pathc

Limited vacuum: 6 * 10-4Pa (clean room, no-load)

Target: arc 6-18 groups, magnetron target 1-2 groups

Power supply: DC power supply, medium frequency power supply, medium frequency power supply, heater power supply, activation power supply, pulse bias voltage power supply

Target: DC magnetic target, medium double target, plane target

Gas time: 5 * 10-4Pa, within 30 minutes

Manual control, semi-automatic, fully automatic, PLC control

Product advantages:

High deposition rate

High adhesion

Good uniformity

Pollution-free

Easy to operate

Energy conservation

Customized processing services