Multi-Arc Ion Vacuum Coating Machine

Simple description:

Danco multi arc ion sputtering coater has excellent performance and simple operation. It is equipped with arc sputtering system, which can be used for vacuum deposition of thin films and coatings.

Product master drawing:

Product labeling:

Coating Machine/Thin Film Deposition System/Ion Coating Machine

Product details:

Arc ion coating machine is a high efficiency,harmless and pollution-free equipment.It has features of fast deposition rate, great ionization rate, large ion energy,easy operation,low cost and large productive capacity etc.

The principle of vacuum electric arc ion coating is based on cold cathode, self-sustained arc discharge plasma evaporation, ionization material, combine pulsed bias technical to improve the energy and activity of deposited particles,and enhance the properties of coating. It can deposit coatings on the surface of metal as well as non-metal.lt can be used for metal film,TiN,TiC,ZrN,CrN,Nickle,Cr and Cu ect. Other compounds film, multi-layer super-hard film, multi-compounds film and titanium nitride with gold film as well.This machine is extensively used for super-hard coating on tools and mould,decorative coatings on car wheel,golf,watches,hard wares,lamp,glasses frame,ceramic and glass.

Our company is improving arc evaporation source of arc ion coating machine,at the same time, we are developing rectangular flat arc evaporation source, and it has been installed into new machines.

The company can design vacuum coating machines of various specifications and models according to user requirements. The vacuum unit and electric control system can also be designed and configured according to user requirements.

Product parameters:

Substrate materials: glass, metal, ceramic, glass, metal (carbon steel, stainless steel, brass), ceramic, plastic, jewelry.

Recommended machine: multi arc magnetron sputtering electroplating machine

Structure type: vertical structure, #304 stainless steel

Coating: multifunctional metal film, composite film, transparent conductive film, reflectivity increasing film, electromagnetic shielding film, decorative film

Film color: gold, rose gold, silver, color, sapphire blue, gun black, brown, dark black, etc

Film types: tin, CrN, ZrN, TiCN, TiCrN, tinc, TiAlN and dlcd.

Consumables in production: titanium, chromium, zirconium

Product use:

Clock and watch industry, hardware, construction industry, telephone shell, accessories, jewelry, glasses frame, glassware, tableware, golf goods, bathroom products, large-size sheets, plates, pipes, pipes, etc.

Product picture:

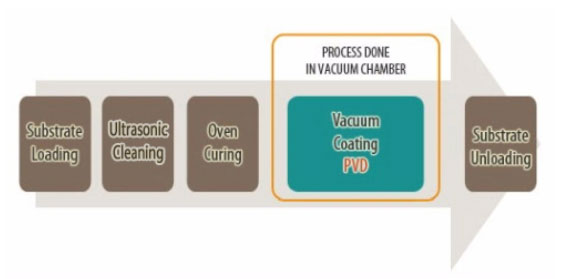

Production process:

Quality control:

Pump: mechanical pump + roots pump + diffusion pump + heat preservation pump (or optional: cryogenic pump, cryogenic pump system)

Gas system: 1-4 pathc

Limited vacuum: 6 * 10-4Pa (clean room, no-load)

Target: arc 6-18 groups, magnetron target 1-2 groups

Power supply: DC power supply, medium frequency power supply, medium frequency power supply, heater power supply, activation power supply, pulse bias voltage power supply

Target: DC magnetic target, medium double target, plane target

Gas time: 5 * 10-4Pa, within 30 minutes

Manual control, semi-automatic, fully automatic, PLC control

Video display:

https://youtube.com/shorts/VvULtddW5ko?feature=share

Product advantages:

Fast film formation and deposition speed;

No waste any gas or liquid. Stable operation and good vacuum performance

Customized processing services

High standard quality control