Magnetron Sputtering Coating Machine

Simple description:

Danke multi arc ion sputtering coater has excellent performance and simple operation, and is equipped with arc sputtering system. Vacuum deposition method for depositing films and coatings

Product master drawing:

Product labeling:

Coating Machine/Thin Film Deposition System/Sputtering Coating Equipment

Product details:

MF sputtering technique has become the mainstream technology of sputtering,what characteristics superior to the DC sputtering are:Overcome the phenomenon of anode disappearance,reduce or eliminate the abnormal arc discharge of target,therefore,improving the stability of sputtering process technology,while increasing the deposition rate of dielectric coating.

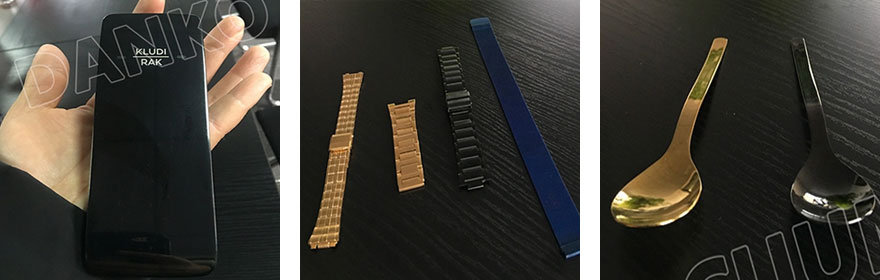

Our company R&D plane target, cylindrical target, twin target, opposite target and various structures of MF sputtering targets. It is widelyused in watchband,watchcases,mobile shell, hard wares, tableware etc. It can deposit TiN,TiC,TiCN,TiAIN,CrN etc decorative coatings.

The company can design vacuum coating machines of various specifications and models according to user requirements. The vacuum unit and electric control system can also be designed and configured according to user requirements.

Product parameters:

Voltage 220V, 380V, customized definition

Chamber material SUS 304

24-hour service, remote guidance

Control system Automatic, manual, PLC

Structure type vertical

Machine Type PVD Machine

Accessories Pump, target, power box

Warranty period of at least one year

Shipping packaging Wood case, container

Size 1600*1500mm

Product use:

It is widely used in various decorative coatings such as TiN, TiC, TICN, CrN, etc. for watch cases, watch straps, mobile phone cases, golf equipment, hardware, tableware, etc.

Product picture:

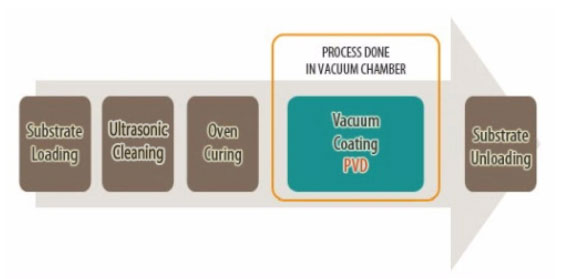

Production process:

Quality control:

Pump: mechanical pump + roots pump + diffusion pump + heat preservation pump (or optional: cryogenic pump, cryogenic pump system)

Gas system: 1-4 pathc

Limited vacuum: 6 * 10-4Pa (clean room, no-load)

Target: arc 6-18 groups, magnetron target 1-2 groups

Power supply: DC power supply, medium frequency power supply, medium frequency power supply, heater power supply, activation power supply, pulse bias voltage power supply

Target: DC magnetic target, medium double target, plane target

Gas time: 5 * 10-4Pa, within 30 minutes

Manual control, semi-automatic, fully automatic, PLC control

Video display:

https://youtu.be/NkLpGYN-cIw

Product advantages:

Fast film formation and deposition speed

Beautiful color and good distribution

No waste any gas or liquid. Stable operation and good vacuum performance

Customized processing services

High standard quality control