Automotive Function Coating Machine

Simple description:

Danko automotive function Coating Machine environmental protection vacuum metallization will not produce VOC, which is an extremely clean process. Thin film vacuum metallization technology enables manufacturers to produce more cost-effective automotive components

Product master drawing:

Product labeling:

Coating Machine/Thin Film Deposition System/Car Lamp/Light Aluminum Coating

Product details:

Car lights special coating machine is including horizontal and vertical structure according to chamber type. The main functions of this machine are high-voltage ion bombardment and finishing aluminum coating and protection coating (SiO) in the chamber at one time. Super-hard coating enhances resistance of aluminum coating and maintains the aluminum film's long-term high reflectivity. The reflective coating for headlights has reached the national test standard. The coating has passed by acid test,salt test and alkali-resisting test ect. The machine is using computer control, monitor operation and process monitoring, whichhave improved production efficiency, ensured the stability and consistency of product quality,reduced the impact of human factors.

The company can design vacuum coating machines of various specifications and models according to user requirements. The vacuum unit and electric control system can also be designed and configured according to user requirements.

Product parameters:

Coating: aluminum, chromium

Color: Silver

Devices: UV lines

Consumables in production: aluminum / chromium line

Product use:

Automobile reflective film, automobile headlamp, tail lamp, turn signal, automobile logo, automobile wheel

Product picture:

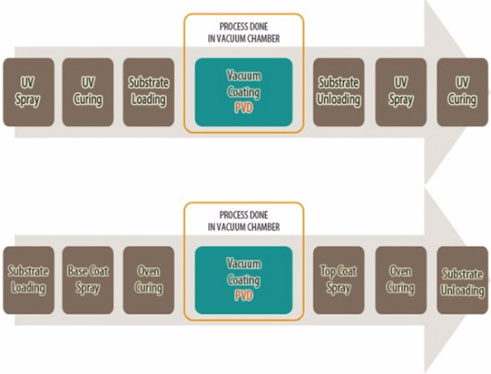

Production process:

Quality control:

Pump: mechanical pump + roots pump + diffusion pump + heat preservation pump (or optional: cryogenic pump, cryogenic pump system)

Limited vacuum: 8 * 10-4Pa (clean room, no-load)

Axis: 6 / 8 / 9 axis

Power supply: resistance heating tungsten wire evaporator power supply, high voltage ion bombardment power supply, thyristor power supply

By manual, semi-automatic, fully automatic, PLC

Video display:

https://youtu.be/m-ulcdSTxV

Product advantages:

Fast film formation and deposition speed;

By using nanotechnology, the process steps of evaporation coating and coating protective film

can be completed in the chamber at one time.

No waste any gas or liquid. Stable operation and good vacuum performance

Customized processing services

High standard quality control