High precision Magnetron sputtering optical coating machine

Simple description:

Danko high precision Magnetron sputtering optical coating machine has excellent performance and simple operation. Advanced process control technology APCs is used: optical monitoring, in-situ temperature and real-time measurement of film stress. The optical film of ICP Assisted Magnetron sputtering is used for low absorption and low stress, and various band-pass films and cut-off films are processed, such as face ID and mid far infrared high transmittance films; Magnetron sputtering of various metals Cu, Al, Cr, Au, Ag, SUS, etc. process development improves deep hole coating. The coating has excellent step coverage performance and is applied to MEMS chip packaging.

Product master drawing:

Product labeling:

Coating Machine/Thin Film Deposition System/Vacuum Metallizing Machine/Optical Coating Machine

Product details:

The modular design of the equipment can be combined with plasma clean unit, magnetron sputtering (SPT) unit, plasma enhanced chemical reaction (PECVD) unit, atomic layer deposition (ALD) unit and plasma chemical reaction etching (RIE) unit to expand the cluster micro nano machining center, covering substrate cleaning and Film deposition (including ultra-thin film) and patterned etching. Meet the strict film deposition uniformity specification, minimize the defects of high stress film, improve the output and reduce the cost.

It ensures the high-throughput and reliable mass production of high-precision optical devices, maintains the film characteristics with excellent performance, such as uniformity, thermal stability and non moisture absorption, and meets the ability of special coating specifications for filters in consumer electronics, automotive sensors and telecommunications accessories.

The company can design vacuum coating machines of various specifications and models according to user requirements. The vacuum unit and electric control system can also be designed and configured according to user requirements.

Product parameters:

Substrate materials: glass, metal, ceramic, glass, metal (carbon steel, stainless steel, brass), ceramic, plastic, jewelry.

Recommended machine: Optical Coating Machine

Structure type: vertical structure, #304 stainless steel

Coating: multifunctional metal film, composite film, transparent conductive film, reflectivity increasing film, electromagnetic shielding film, decorative film

Film color: gold, rose gold, silver, color, sapphire blue, gun black, brown, dark black, etc

Film types: tin, CrN, ZrN, TiCN, TiCrN, tinc, TiAlN and dlcd.

Consumables in production: titanium, chromium, zirconium

Product use:

Clock and watch industry, hardware, construction industry, telephone shell, accessories, jewelry, glasses frame, glassware, tableware, golf goods, bathroom products, large-size sheets, plates, pipes, pipes, etc

Product picture:

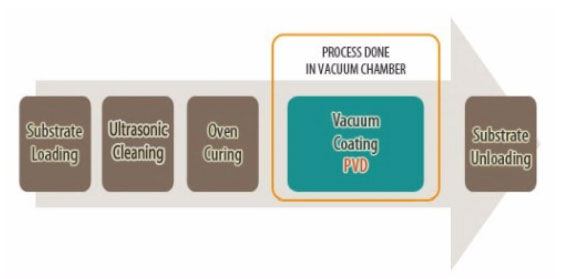

Production process:

Quality control:

Pump: mechanical pump + roots pump + diffusion pump + heat preservation pump (or optional: cryogenic pump, cryogenic pump system)

Gas system: 1-4 pathc

Limited vacuum: 6 * 10-4Pa (clean room, no-load)

Target: arc 6-18 groups, magnetron target 1-2 groups

Power supply: DC power supply, medium frequency power supply, medium frequency power supply, heater power supply, activation power supply, pulse bias voltage power supply

Target: DC magnetic target, medium double target, plane target

Gas time: 5 * 10-4Pa, within 30 minutes

Manual control, semi-automatic, fully automatic, PLC control

Product advantages:

Fast film formation and deposition speed;

Beautiful color and good distribution

No waste any gas or liquid. Stable operation and good vacuum performance

Customized processing services

High standard quality control